Pat Harkins: ‘Get a bigger hammer’

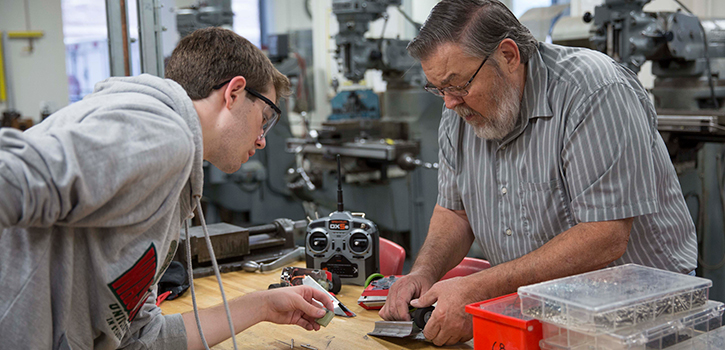

The machine shop in Urbauer Hall is a place where Engineering students learn to use hand and power tools to turn their ideas into reality. But that’s not all they learn there. With Pat Harkins at the helm of the shop for the past 26 years, thousands of Engineering students have learned persistence, patience and how to address problems with sometimes unconventional solutions.

While Harkins’ official title is technician, alumni say he is much more than that: mentor, teacher, surrogate father and friend. Working in a machine shop includes a significant amount of hands-on skills, but Harkins also provides life and people skills through his sense of humor and unpretentious charm.

“Pat Harkins: There might well be no two other words that, in tandem, compel such a fond grin from those who have had the privilege of crossing paths with the legend himself,” says Eric Jensen, who works in business development at Boeing Phantom Works and earned a bachelor’s degree in mechanical engineering in 2008. “My admiration of Pat stems from his genuine compassion for students, his innate skill for fostering an environment wherein aspiring engineers are free to learn by experience, and an incomprehensible ability to resolve any problem with two grunts and a bigger hammer.”

A lifelong St. Louisan, Harkins came to Washington University in 1988 to run a machine shop. Over time, he has picked up more responsibility, adding teaching to his résumé. This fall, he is teaching four classes — two sections of Machine Shop Practicum and two sections of Mechanical Engineering Design and Build. In the spring, he adds another class. He also works with the Formula SAE (Society of Automotive Engineers) Race Car team, which builds a new car each year, and the Battle Bot Club.

When students start working with Harkins, often they aren’t sure if some of his catchphrases are serious or not.

Steven Schleibaum, a member of the FSAE team, recalled a couple of Harkins gems.

“Having Pat around literally saved our FSAE team more times than I can count with his unconventional and out-of-the-box solutions,” says Schleibaum, who earned a bachelor’s degree in mechanical engineering in 2013. “These usually involved ‘getting a bigger hammer,’ and if that didn’t work, it was clearly for a very specific and oftentimes true reason: we weren’t holding our mouths right.”

At the Formula SAE Michigan Collegiate Design Series in May 2013, the differential on the FSAE race car came apart during a test run 90 minutes before the end of the day’s events. The team had to remove and dismantle the part, diagnose the problem, fix and reinstall it all within an hour or risk losing points. Harkins quickly took control of the situation, and within five minutes he had begun the repair “with nothing but a file and the biggest hammer in Michigan,” Schleibaum recalls.

The repair was a success, and the team completed all of the dynamic events and had the best finish of any WashU team competing in the event.

“You trusted him because it was obvious that he cared. In fact, he cared enough not only to praise you when you did well, but set you straight when you messed up.”

— Rich Ockers

“Pat was the sole reason for this accomplishment,” says Schleibaum, an engineer at Chrysler Institute of Engineering,

Working with the FSAE team is a natural choice for Harkins, who has been a car enthusiast since he was a young boy. In fact, he learned to drive at age 10, and his grandfather gave 13-year-old Harkins his own truck. Since then, working on cars has been his hobby and sometimes side business. He had to have the side business to fund his own habit of racing dragsters at local raceways.

“In the ’70s, my neighbors would bring their cars and some oil over, and I’d charge 50 cents for an oil change,” Harkins says. “A tune-up was $2 if they brought the parts.”

But it wasn’t just simple maintenance that Harkins did in his home shop — he built race cars, street rods and show cars, and chassis parts and roll cages for race cars. He also bought old cars to strip them of their parts to sell.

“At one time I had, oh, probably 15 projects sitting in the yard,” he recalls.

How many cars has he had in his lifetime?

“Oh, you don’t want to know,” he says with a laugh and a twinkle in his eye.

Now, he has just three cars, including a red 1998 Corvette that was a 60th birthday present from his wife, Carolyn.

Rich Ockers, now an MBA student at the Olin Business School who earned a bachelor’s degree in mechanical engineering in 2008, said Harkins quickly became his mentor and friend.

“Pat is one of those special guys that you never forget and still think the world of even after they just finished adjusting the extent to which your head was screwed on properly.”

Armen Nazarian, an integration engineer with Tesla Motors, said some of his fondest memories of his years at WashU were learning to use the mill as a freshman, spending countless hours bouncing design ideas off Pat in his office on some graph paper, and fixing a broken suspension linkage with nothing but a bucket of washers, a Dremel tool and a MIG welder when the FSAE team competed in Michigan in 2013.

“As adviser to the Formula SAE team and a racing and fabrication expert, Pat taught me everything I know that is worth knowing about designing and building things — most importantly to never give up on finding a way to make things work (even if the solution requires a really big hammer),” says Nazarian, who earned bachelor’s degrees in mechanical engineering in Engineering and in managerial economics and strategy from the Olin Business School in 2012. “Year after year, Pat’s seemingly endless wisdom and patience help students find their passion in engineering by gaining hands-on experience building the projects they dream up.”

“Year after year, Pat’s seemingly endless wisdom and patience help students find their passion in engineering.”

— Armen Nazarian

Nikolaos Rigas, PhD, who earned a doctorate in chemical engineering in 1991 and is now senior scientist and director of the SCE&G Energy Innovation Center at Clemson University, was the first graduate student Harkins worked with at Washington University. He says Harkins taught him more than how to use the equipment he needed to do his work and how to keep the shop clean.

“I was a reservist with the Navy while I was working on my PhD,” Rigas says. “I was recalled to active duty suddenly one day in support of Desert Shield and eventually Desert Storm. Pat became very emotional over the issue as well as angry. I remember he had tears in his eyes as I left the lab that day, and he hugged me telling me that he expected me back and to finish this degree I started. By then he had become my mentor and surrogate father.”

Harkins says since his wife retired, she asks him often when he plans to do the same. “I don’t want to retire,” he says. “I have too much fun.”

Memories about Pat Harkins from Engineering Alumni

“I had a job in the machine shop with Pat my senior year at WashU, and it was one of the best experiences I had at the school. He taught me an immense amount of really useful skills and was so patient and kind. It's uncommon to encounter a teacher who so perfectly balances providing guidance with leaving a student to figure things out alone. He was also so open and giving with his time and advice in a way that's rare to find with a professor or boss, especially one with so many demands on his time. Pat was an incredible mentor, and I often think about the many hours spent in the basement with him with much fondness.”

— Lauren Shuler

B.S., Civil Engineering, 2010

Project Engineer at Natural Systems Utilities & Masters Student at University of Florida

“Working with Pat was one of the best memories I had of engineering school at WashU. He was really patient and always had great suggestions for projects. Some of my favorite memories were working on some of my hard drive clocks down in his machine shop and building a small engine that powered a fan with his help.”

— Andrea Flores

B.S., Mechanical Engineering, 2002

Instructional Designer at Harvard School of Public Health

“I took Pat's class and worked for him via the work/study program. I would advocate for any mechanical engineer to take his class. He is a great teacher/mentor.”

— Damon Magnuski

B.S., Applied Science, 2001

President at PeopleHedge Corp.

“Pat Harkins was a huge influence and mentor to me and the whole Washington University in St. Louis Formula Society of Automotive Engineering Team. Without him and his guidance as our faculty mentor, we wouldn't have been eligible for the national competition, but most importantly, probably wouldn't have been able to design, fabricate, and present such a fabulous car at both of the 2005 and 2006 competitions that I participated in. Building these racecars was definitely a major highlight of my time at Washington University. Pat would push us to think outside the box and would always be a helping hand in the machine shop. He is a great educator and truly cares about the success of his students. I wish every engineering student were required to take his machine shop class. It really gives the student a feeling for what is possible and provides you with a whole new design perspective.”

— Melissa L. Holtmeyer, Ph.D.

B.S., Mechanical Engineering, 2006; M.S., Mechanical Engineering 2007; PhD, Environmental Engineering, 2012

Energy and Environment Policy Fellow

AAAS Congressional Science and Engineering Fellow

“Pat Harkins is the heart of the Mechanical Engineering Department. Whether he's helping the FSAE team, the Nanosat team, wide-eyed freshmen or university professors, his remarkable experience and cheerful, laid-back disposition always brings an air of calm and confidence.”

— Mark Goldman

B.S., Mechanical Engineering, 2010

Senior Mechanical Design Engineer

Tesla Motors, Inc.

“I remember Pat Harkins as somebody who was always looking for ways to be helpful. Sometimes I would go to him with a very specific question and other times I would stop to just discuss an idea that I had, but was lacking the details to make my idea come to life. Either way, Pat always seemed happy to put up with my crazy questions and discuss possible solutions to help me make progress. I will always remember his sincere interest to help students and his willingness to share his knowledge without making you feel inferior.”

— Brian Mann, PhD

M.S., Mechanical Engineering, 1998; PhD, DSc, Mechanical Engineering, 2003

Associate Professor

Dynamical Systems Lab

Duke University

“Pat should teach a class in patience. Not only does he help kids from class but also those of us from clubs who constantly bug him for advice. He couldn't be more helpful or supportive.”

— Colin Graham

Current Master’s Student

Graduate student, member of WUSTL Rocket Club

“I took Pat's introductory machining class my freshman year in the Fall of 2003. I had always been interested in metalworking and machining, but had no real experience prior to the class. I later started working for Pat in the engineering machine shop and continued working with him until I graduated in 2008. I also participated in Formula SAE during my years in the engineering school, for which Pat was the faculty adviser. He spent a lot of time helping us out with a project we were pouring our heart and soul into. As a 'gear head' himself, Pat understood the time and effort the project took, and was willing to help out however he could, especially when a problem required Pat's 'magic hammer' and experience that only 40+ years doing what he did could help resolve. He is one of the kindest, most patient, and smartest people I've been around in my time at Washington University and in professional career as an engineer with Cummins Inc. Though he didn't hold a prestigious PhD like most of my other professors, I'd put his creativity and IQ against anyone I've worked with. I am grateful for the time I was able to spend working with for Pat both as a student, colleague, and friend. I would not be where I am today professionally without his guidance and mentorship when I was a student.”

— Ryan Hyslop

B.S. Mechanical Engineering, 2008

Performance/Combustion/Emissions Engineer at Cummins Inc.