Additive manufacturing, high-speed imaging focus of Weisensee’s CAREER Award

Patricia Weisensee will use infrared imaging to study 3D printing of metals

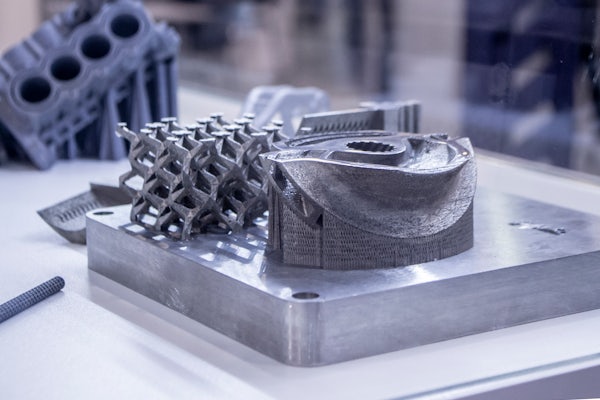

Additive manufacturing, a type of 3D printing with metals, has been used since the 1980s to create biomedical implants and parts for airplanes and automobiles. The process allows for rapid prototyping of a model and more complex part geometries as compared with traditional casting, but the quality varies from piece to piece. A Washington University in St. Louis engineering researcher plans to improve the quality of the products by studying the underlying physical processes using a unique imaging setup.

Patricia Weisensee, assistant professor of mechanical engineering & materials science, will look at the effects of additive manufacturing process on the material properties of the printed medals with a five-year, $557,000 CAREER Award from the National Science Foundation. CAREER awards support junior faculty who model the role of teacher-scholar through outstanding research, excellence in education and the integration of education and research within the context of the mission of their organization. One-third of current McKelvey Engineering faculty have received the award.

Weisensee, whose research focuses on understanding the interplay of fluid dynamics, heat transfer and liquid-solid interactions of droplets and other multi-phase systems, said additive manufacturing is frequently used to build complex structures without having to use screws or welding or to make repairs without having to case new pieces. The process uses fewer parts, is generally lighter in weight and lower in cost and requires less human labor to construct. However, the quality of the products is inconsistent, which has limited its more widespread use.

“Because metals are not transparent, we don’t have ways of being able to tell whether the outcome will be a good quality or not while it’s printing,” she said. “Because additive manufacturing is a fairly complex process that requires frequent reheating of the materials, the reheating changes the microstructure, and that influences the mechanical properties. We want to learn how these influence each other.”

In her research, Weisensee will use the Laser Engineering Net Shaping (LENS) method in which a laser locally melts the substrate and then blows metal powder, which could be a different material than the substrate, into the melt pool. The powder particles melt inside the melt pool, and when the laser moves to a new position on the substrate, the melt pool solidifies.

“This method requires less powder and has more flexibility in terms of changing metals and materials along the way than some of the more commonly used techniques, such as powder bed manufacturing,” Weisensee said. “You can start with one metal on the bottom, then slowly transition to different metals.”

This creates a new alloy with unknown properties, she said.

“When you print two metals next to each other, there is a small transition zone that behaves differently from the rest of the piece,” she said. “The thermal properties, crystal structure and cooling rates can be different. These different properties lead to a higher risk of cracking.”

Weisensee and her team will employ a high-speed imaging technique to see how the particles behave on the surface along with a high-speed infrared camera to characterize the thermal behavior of the melt pool. They can then couple this information to the metallurgical microstructure to better understand the coupling of the melt pool dynamics, thermal history and part properties, she said. This knowledge can help lay the foundation to implement for reliable manufacturing processes.

As part of the work, Weisensee will expand an outreach program at a local private middle school for girls from low-income families to teach 3D printing and high-speed imaging. She also plans to conduct a teacher workshop. In addition, she plans to work with senior design students in the Department of Mechanical Engineering & Materials Science to develop a 2.5D droplet-based chocolate printer kit to introduce thermal-fluid sciences.