Condensation key to climate-friendly power generation

Patricia Weisensee won an NSF grant to study a condensation pathway with green potential

To combat climate change, Patricia Weisensee, assistant professor of mechanical engineering & materials science in the McKelvey School of Engineering at Washington University in St. Louis, is working to increase energy efficiency, particularly in power generation, air conditioning and refrigeration systems.

Weisensee won a $351,971 grant from the National Science Foundation to support a new study of condensation in fluid refrigerants. By determining the conditions necessary for these fluids to condense into droplets, rather than films, Weisensee aims to increase heat transfer rates in refrigerant mixtures. Better heat transfer leads to increased efficiencies in applications such as power plants and savings in energy normally lost as waste heat.

“I’m interested in low-temperature waste heat recovery, where you actually produce electricity from low-temperature heat sources around 150 degrees Celsius or lower,” Weisensee said. “You can’t really use water for that. Its thermodynamic properties aren’t very good in that temperature range.”

However, nonaqueous fluids used as refrigerants have low surface tension, which causes them to condense as a film, creating thermal resistances in the system and leading to poor thermal performance.

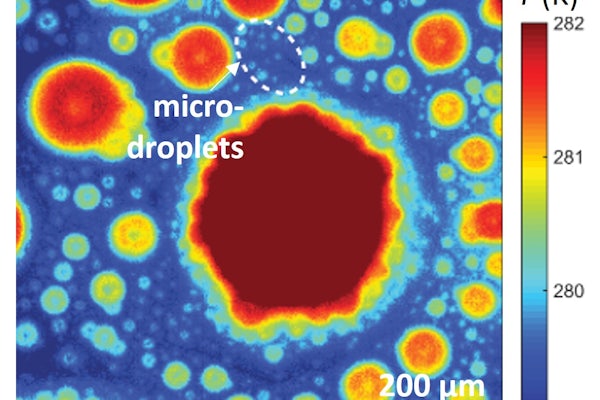

“With this grant, I’m exploring whether we can find refrigerant mixtures other than water and alcohol in combinations that allow us to generate what’s called Marangoni condensation, where a liquid film develops into droplets,” Weisensee said. “When the film breaks and droplets form, that allows heat transfer to happen more efficiently, and that then increases the overall performance and efficiency of the entire thermodynamic cycle.”

By creating gradients in the surface tension of refrigerant mixtures through variations in the temperature and composition of the fluids, Weisensee said she plans to induce instabilities that lead to the formation of droplets, or Marangoni condensation, increasing heat transfer rates dramatically.

“Despite the recent news about fusion power, that’s still probably decades away. For now, most power plants –nuclear, solar, coal, whatever – they all run a steam cycle where a working fluid is expanded into steam to run through a turbine, then condensed back into a liquid so it can be pumped through the cycle again,” Weisensee said. “We’re looking at the condenser part, where improved refrigerant mixtures would make the overall cycle more efficient, giving us a lot more bang for our buck, where the bang is electricity output.”

“Tapping into the waste heat that is, right now, just dumped into the oceans, into the rivers, into the atmosphere, and not used for anything won’t solve the energy problem, but it would be one piece of improving our energy portfolio going forward,” Weisensee said.