Design/Build/Fly

Members of the Design/Build/Fly team take their love of engineering to create an aircraft that meets certain specifications for a national competition. See how they fared this year

Building an aircraft from the ground up is no easy task. Building one that can compete in an international competition is even more difficult. Nevertheless, each year, members of Design/Build/Fly (DBF) in the McKelvey School of Engineering take on the challenge.

For many of them, building a plane isn't so much a school project as it is a passion.

"I love engineering," says Austin Stover, a senior majoring in electrical engineering. "I love building stuff. I like figuring out challenges, and without WashU DBF, I don't know what I would be doing on weekends."

Sponsored by the American Institute of Aeronautics and Astronautics, Design/Build/Fly challenges teams of students from top engineering programs around the world to — well, design, build and fly their own aircraft. Teams must build a remote-controlled aircraft according to strict design guidelines, then successfully fly it through a course that includes challenges, such as 360-degree turns, payload drops, and takeoff and landing specifications.

"The competition is an incredibly positive environment because everyone knows exactly what goal you are trying to achieve," says Taylor Tuleja, who is earning a master's degree in mechanical engineering after earning dual bachelor's degrees from WashU and Hawaii Pacific University. "You see how different schools thought of different ways to solve the problem."

Design

Before their aircraft can hit the runway, though, the students first need to determine what they're building. Along with their plane, teams submit a lengthy design report that makes up a big portion of their final score.

"They're often very harsh grading those reports, so few teams score well," Stover says. "It's basically a compilation of your entire design, and while it's a lot of work, it can also be good to reflect on why you're doing what you're doing."

The team has until March to work on its design report, allowing members to tweak the design as necessary before the final competition. It aims to save teams time and money spent on poor designs, and WashU DBF takes full advantage of the opportunity.

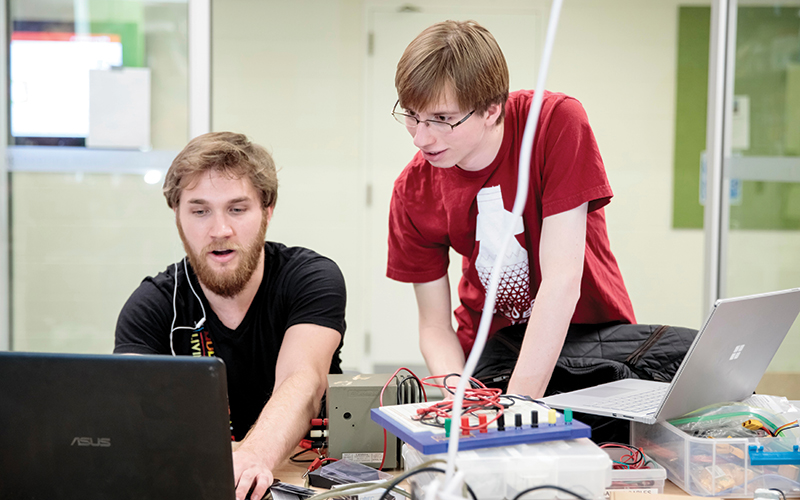

"We have the tools that allow us to do a bunch of simulation work before we start building," says Tuleja, the club's administrative president. "Some members of our team have actually made a kinematics simulation software to help us do air optimization prior to building."

Build

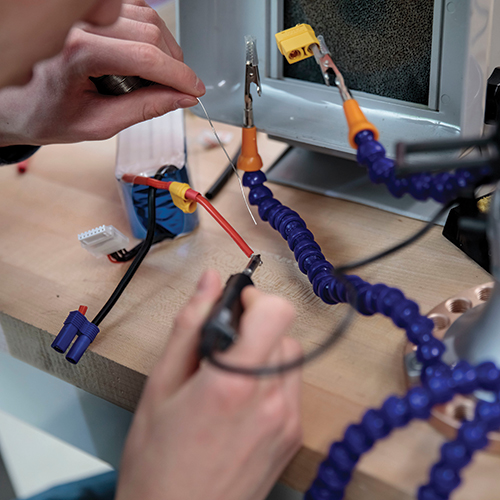

Once the build is underway, nearly 40 team members are on hand to help code, manufacture and assemble the plane — a time-intensive project.

“Odds are, if you’ve ever passed by the makerspace, there’s somebody from Design/Build/Fly in there,” Tuleja says. “Leadership meets every Friday and will stay in there until midnight. We have meetings that start at 11 a.m. on Saturdays. We stay until 5 or 6 and take a break for dinner — and sometimes come back.”

For many team members, the hands-on building experience is their first opportunity to work with materials and build prototypes. More experienced club leaders even gather resources such as YouTube videos to help prep new members for the build.

“All of the guys and girls on the team are very open and friendly and willing to teach anyone who wants to join the club about aerospace engineering,” Tuleja says. “Even if you know absolutely nothing, our motto is ‘Come, and whatever you’re willing to put into it, you’ll get out of it.’”

Fly

At competition time, the team loads up and heads to either Wichita, Kansas, or Tucson, Arizona — the competition site alternates each year. Once there, team members continue refining their plane until it's time to fly.

"You put all of your time during the year building this plane, and you don't realize how many revisions you're going to have to do at competition when things break and stuff doesn't go as planned," Stover says. "Maybe your design is finished and you tested it, but you haven't tested it in 20 mile-per-hour winds or in the rain. It's definitely a lot of pressure, but that is where you learn the most as an engineer."

In 2018, the team placed in the top five for its design report, but gusty winds hindered the plane's performance.

"It was in Wichita, Kansas," Tuleja said, "and we were flying a very tiny plane."

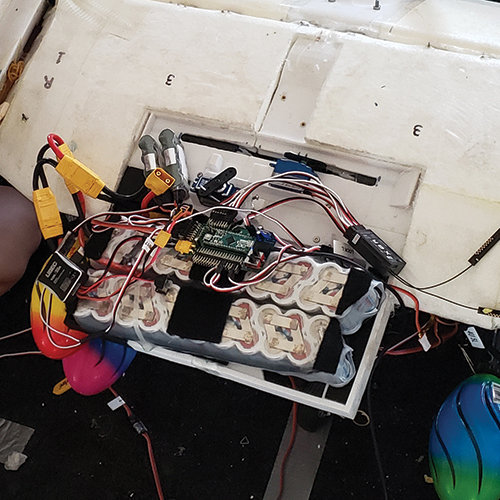

The team went in a different direction this year, designing a plane with a 2-meter wingspan. The team placed 64th out of 104 teams.

"Unfortunately, we did not fly during the competition due to issues with our wing folding mechanism, but we did fly earlier, before the competition," Stover said. "This year's competition taught us how to better divide our time between the different complexities of the aircraft components."

“We had one of the riskiest and most complex designs at competition; we tried to incorporate thrust vectoring into our aircraft this year, which no one else attempted. I think we placed so high on the report because of the complexity of our design, and I think the judges were impressed by how incredibly advanced our analysis of design was.”

— Taylor Tuleja

"We had one of the best design reports, which is how we were able to place so high without a flying aircraft," Tuleja said. "And although we were only 64th, we still beat many top universities like Columbia and Cornell."

Win or lose, team members say the experience is an invaluable one. Stover credits his work with the team as part of the reason he changed his major from mechanical engineering to electrical & systems engineering.

"In DBF, I learned a ton about circuits and the logic that went into designing and sizing a motor electronics speed controller," Stover said. "This is the kind of logical electrical engineering stuff that I really grew passionate about."

SimDev team goes open source

WashU’s DBF team includes an advanced Simulation Development Team that allows members to test designs before building. This year the team, along with graduate adviser Kevin Hainline developed a program in MATLAB for aircraft analysis. It will be available as an open-source program and published on the MathWorks website.

“This is an incredible honor, for not only our team and Kevin, but for the entire university,” Tuleja says. “It will probably be used by every Design/Build/Fly team in the world after being published, as well as many other people doing remote-controlled aircraft design.”

Back to Engineering Momentum