McKelvey Engineering alumni pitch in to COVID-19 effort

McKelvey School of Engineering alumni are doing their part to help out during the COVID-19 pandemic, both as part of their work and on their own time. Here are a few we learned about

As the world adjusts to a new normal during the COVID-19 pandemic, many individuals are using their skills and talents to help, from sewing masks to holding food drives to running errands for elderly neighbors. McKelvey School of Engineering alumni are doing their part as well, both as part of their work and on their own time. We know there are many out there, but here are a few we learned about:

Nick Colarelli, MS,

Nick Colarelli, MS,

electrical engineering, 1986

Nick Colarelli, executive vice president at Hunter Engineering in St. Louis, is on a team at Hunter that is providing engineering and manufacturing resources to build Powered Air Purifying Respirators (PAPRs) for health care providers on the frontlines. Up to 30 percent of health care workers who wear N95 masks get infected with COVID-19.

Taking an idea from Jennifer Delaney, MD, an instructor in clinical medicine at Washington University School of Medicine, to build PAPRs from recycled CPAP machine motors, the Hunter Engineering team worked with the technical department of John Burroughs School to design and build a prototype with assistance from PASCO Systems, a local company that provides robotic automation and palletizing. The team is streamlining a manufacturing process to convert recycled CPAP machine motors into PAPRs. As of late April, Hunter had collected more than 300 donated CPAP machines to salvage the blower motors.

Nathan Eberlin, MS,

Nathan Eberlin, MS,

information management, 2009;

MS, project management, 2010

Nathan Eberlin has been working with flattenthecurvestl.com's Face Shield Initiative printing face shields and ear savers for masks for the past several weeks. Over four weeks, he 3D-printed 115 face shield frames using eight rolls of filament. When he began, the process took eight hours per frame, but he reduced the time to four hours per frame using his two 3D printers.

Separately, Eberlin printed about 200 ear savers. He provided Alton Memorial Hospital in Alton, Illinois, where his mother works, 150 face shields from the initiative and 150 ear savers.

Overall, the Face Shield Initiative delivered more than 8,000 face shields provided to medical professionals. The initiative is winding down due to material shortage and commercial manufacturers now meeting demand to supply medical centers, however, the initiative will respond to new requests.

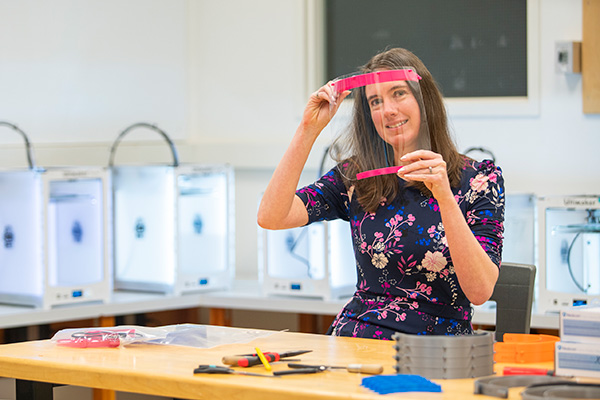

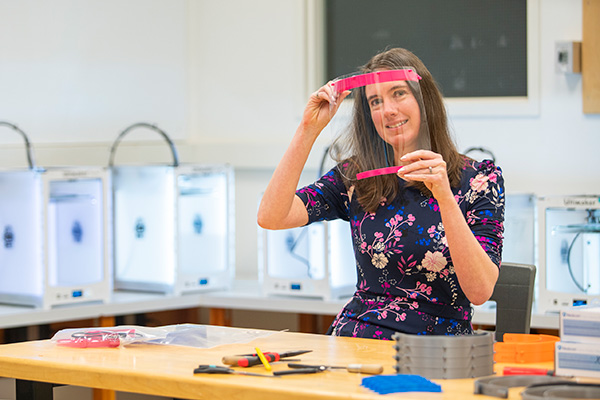

Stephanie Willerth, MS, PhD,

Stephanie Willerth, MS, PhD,

biomedical engineering, 2008

Stephanie Willerth is director of the biomedical engineering program at the University of Victoria in British Columbia, Canada. She and her team delivered 1,000 face shields to Island Health at no cost with plans to distribute 4,000 more in the coming weeks. The face shield's components are being produced in local businesses, research labs and even homes across the region, then are dropped off for Willerth's team to inspect, assemble and package. In addition, a machine in her lab that emits ultraviolet rays is used to sterilize the shields and their packaging before they are sent to Island Health.

"We've been linking with groups that are able to machine components and 3D print from all over the Island. It is definitely an amazing community effort," Willerth said.

In addition, Willerth is supervising a cohort of Engineering co-op students this summer who are all working on challenges related to COVID-19.

Michael Nasuta, BS,

Michael Nasuta, BS,

biomedical engineering, 2008

Michael Nasuta is a core team leader at Becton Dickinson (BD) in Baltimore. BD recently launched its fourth test to detect COVID-19 globally. The molecular test can detect viral RNA in two to three hours on the thousands of existing BD MAX instruments installed in laboratories worldwide. The company has employees working around the clock to manufacture the tests, he said.

"Everyone is focused on getting the product to market as soon as possible," Nasuta said.

Nasuta ensures that the company's instruments that analyze these tests run with minimal errors.

Nasuta said it generally takes a few years to get an FDA-approved test on the market, but BD has been able to bring four new tests to market in only a few months, which has provided test results to millions of patients.

"Governments, regulatory bodies and industry have moved mountains to make what has happened possible," he said. "The people who are in the trenches are very proud of the work we are doing that has impacted millions of people."

Bob Parks, BS,

Bob Parks, BS,

electrical engineering, 1973

Bob Parks has organized nearly 40 3D printer owners and volunteers in the Chicago area to create, package and distribute full-face protective shields. As of May 2, his "Noble Army" had provided more than 5,000 full-face protective COVID-19 face shields to hospitals, the Chicago Food Depository and other health care organizations in Cook County, in only one month of operation. Now, they are creating 200 face shields a day and have been recognized by the Cook County Sheriff's Office for their contributions.

Parks, who is retired, saw the need for more protective equipment through a neighbor who is a nurse in an intensive care unit. Using a design available online with his 3D printer, a plastic page protector, a three-hole punch and an elastic band, he created a prototype in about three hours. Her ICU supervisor was so impressed that he ordered 70 face shields as soon as he could get them.

Knowing he couldn't do it alone, Parks used social media and email to recruit helpers, and in under 24 hours, he had a group of volunteers running 20 3D printers to create the plastic headset, which they dropped off at Parks' home for sterilization and packaging with other needed parts for delivery. Since then, he and the group revised the design to eliminate the need for elastic, which is in short supply nationwide.

Parks wants to share what he's learned through the process with others who would like to mobilize their own "Noble Army." He and his wife, Susan, have documented procedures and built management tools, setting up a website with a manual on how to make all of this happen. He is available for guidance and wants to be in a position to guarantee the success of others and see growth in factories go viral.

"You have one shot on earth to try to make a difference on this scale," he said. "When this opportunity popped up, I was like a bulldog to the jugular — it is the one opportunity in my life to really make that sort of impact."

Parks invites those interested to contact him at ShieldCrowdFactory@gmail.com. His website is FaceShieldFactory.org.

Mona Stone, BS,

Mona Stone, BS,

biomedical engineering, 2005

Mona Stone, DDS, a maxillofacial surgeon in Dallas, is part of an organization providing personal protective equipment to health care workers in need. The group, Real Heroes Need Masks, donated 20,000 surgical masks in its first eight days and raised thousands of dollars in two weeks. Since then, it has donated 33,000 masks to 33 hospitals in Texas, New York, Illinois, Louisiana, New Jersey, California, Indiana and Georgia.

The group has worked with physicians to set up donation centers at outpatient clinics in more than 30 cities across the country where masks can be donated. At the end of April, the group was preparing to ship another 30,000 surgical masks to hospitals in Dallas, New Orleans and other cities where the need is great.

Stone has a friend and fellow surgeon who is getting an MBA at Indiana University and was participating in an idea sprint weekend for COVID-19 in March. Her friend asked Stone to join the team, which decided to coordinate purchasing FDA-certified surgical masks at a deep discount and distribute them to hospitals nationwide through a growing network of volunteers. Also on the team is WashU alumna Jun Yang, who earned a doctorate in finance from Olin Business School in 2004.

Stone said she and several other physicians used their social media accounts to spread the word about their campaign.

As a member of the medical profession, Stone saw firsthand the need for equipment and is proud to be a part of it.

"It means the world because I truly know that when you have proper protection against virus bacteria, we are able to save lives," she said. "I know that this has helped in reducing rates of transmission in the hospitals that have gotten these masks. Knowing that there are a lot of people out there going through this hard time, but they took the time to help shows that there's a lot of good people out there. That makes me happy and proud."

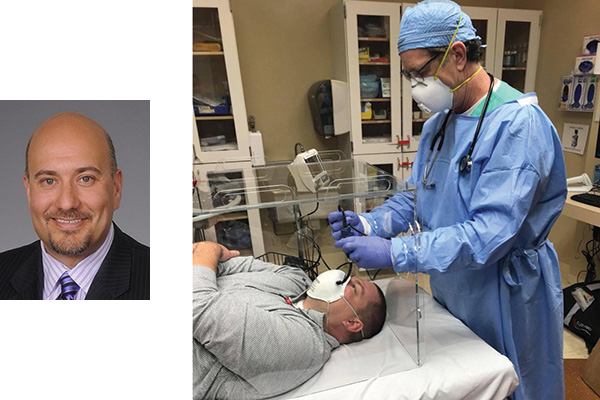

Scott Schienvar, BS,

Scott Schienvar, BS,

chemical engineering, 1994

Scott Schienvar, vice president of operations, professional productions division at L'Oreal Corp. in New York, and his team used an open-source design to create an intubation box designed to protect doctors from aerosolized particles during the intubation procedure. The lucite box is designed to pack, ship, assemble, clean up and store easily for use at hospitals nationwide.

Schienvar said he and his team first learned about this open source project on a website shared via a colleague in Taiwan. After trading emails for 12 hours, some of his coworkers made it to full production in 48 hours, he said.

Back to Engineering Momentum