EECE and CSE collaborate in a fusion of synthetic biology, AI

A multi-department partnership looks to lower cost and time when it comes to the biomanufacturing process

The odds of success in yeast are rising.

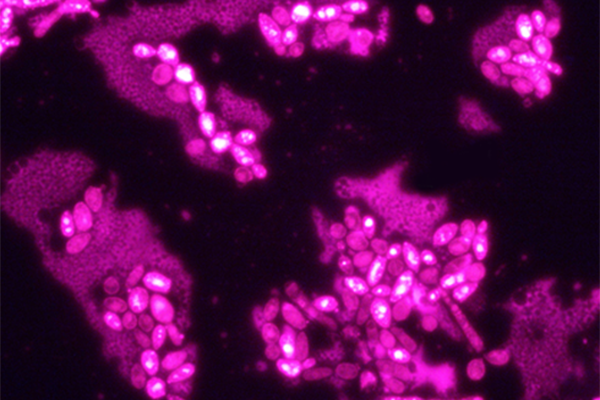

Partly through a three-year National Science Foundation (NSF) grant of $940,000, a collaborative effort is taking place between the Department of Energy, Environmental & Chemical Engineering (EECE) and the Department of Computer Science & Engineering in the McKelvey School of Engineering at Washington University in St. Louis to focus on three yeasts for a result of low-cost, effective AI-enhanced biomanufacturing. The group aims to use machine learning and modeling for the development of the yeasts.

Yixin Chen, professor of computer science & engineering, is helping EECE faculty develop the machine learning strain design; and McKelvey Engineering alumni Jeff Czajka, who earned a doctorate in 2021, and Di Liu, who earned a doctorate in 2017 and was a student in Professor Fuzhong Zhang’s lab, are co-investigators on the grant, along with Keesoo Lee, a professor of microbiology at Lincoln University, a historically Black college and university (HBCU). The Department of Energy is providing $200,000 to support collaboration with Liu, now a staff scientist at Sandia National Labs.

With a focus on oleaginous, or oily, yeasts, which allow for biosynthesis of pharmaceuticals and biofuels from substrates, the hope is to move the biomanufacturing process away from long and expensive test cycling.

“Artificial intelligence touches every aspect of our lives,” said Joshua Yuan, the Lucy & Stanley Lopata Professor and chair of Energy, Environmental & Chemical Engineering. “We see this in chemical engineering and being involved in process data and the most optimal ways of productivity.”

A Problem of Money and Time

Synthetic biology tools can engineer microbes to produce many target products, Chen said. However, multiple Design-Build-Test-Learn (DBTL) cycles are needed from slowdowns from pathway engineering.

Still, DBTL often is less effective after the early going of cycles and strain development may get to the point of little to no technological improvement.

The potential answer: AI.

“They are often now trying to apply machine learning and data science to better predict biological functions,” Chen said. “The challenge is trying to discover new design and new bioreactors and the cycle of DBTL can be expensive. You would need to design then do viewing in a lab then see the behavior and collect data, learn from it and go back to the cycle test. Imagine how expensive and time consuming that process can be. What we want to do is create a ‘shorthand’ for the cycle by learning from existing data.”

Normally for machine learning, he said, there are large datasets from which to train models, particularly in computer vision and image processing. However, in biology, there may only be hundreds of data samples, which makes the training more challenging, since the more training data there is, the better trained model.

“We have data points for developing technology for such situations and, by doing so, we can significantly reduce the cost of designing new bioproducts,” he said. “Another challenge is how to collect and extract data from multiple sources. Successfully training machine learning models on limited data can be a huge advantage.”

For this project, they will focus on database enhancement and, using AI technology through transfer learning, they can use the data for yeasts to learn important patterns.

The project, titled Development of a Machine Learning Pipeline for Assisting Strain Design of Nonmodel Yeasts, also involves a collaboration in HBCU student training in biomanufacturing, entrepreneurship and data science. Students from Lincoln University will come to Washington University to do research, learn from a custom curriculum and expand their potential opportunities in related fields through the project. For example, Missouri is a fermentation leader in the country, and this work will give them strong, related experience in that industry. Lee will visit Washington University to help kick off the collaboration.

“We are very excited to have students from Lincoln University be a part of this effort and to mentor them in many ways,” Yuan said. “We want this to be an experience they look back on as instrumental to their careers. If we can make strides in biomanufacturing and give students the tools they need, this can be a successful project on many fronts.”

Click on the topics below for more stories in those areas

- Alumni

- Graduate Students

- Research

- Computer Science & Engineering

- Energy, Environmental & Chemical Engineering