It's easy to start your application.

COVID-19 WashU/BJC Maker Task Force (MTF)

A WashU/BJC Maker Task Force was established to make recommendations and provide solutions for Personal Protective Equipment (PPE) and medical supply prototypes due to challenges caused by COVID-19. The task force included technical experts and leaders from McKelvey Engineering, Washington University School of Medicine (WUSM), BJC Supply Chain, BJC/WUSM Healthcare Innovation Lab, and the broader St. Louis "maker" community.

The Results: Through tremendous efforts to discover, test, prototype and produce a variety of solutions, the task force resulted in:

- Clinician approved prototype and production of 1,000 face shields

- Clinician approved prototype and identification of local company to sew 250,000 isolation gowns

- Two shelf-ready prototypes for masks and identification of local manufacturer to produce 70,000 cloth masks

- 3,000+ disinfected N95s and numerous N95 prototypes with associated pending publications

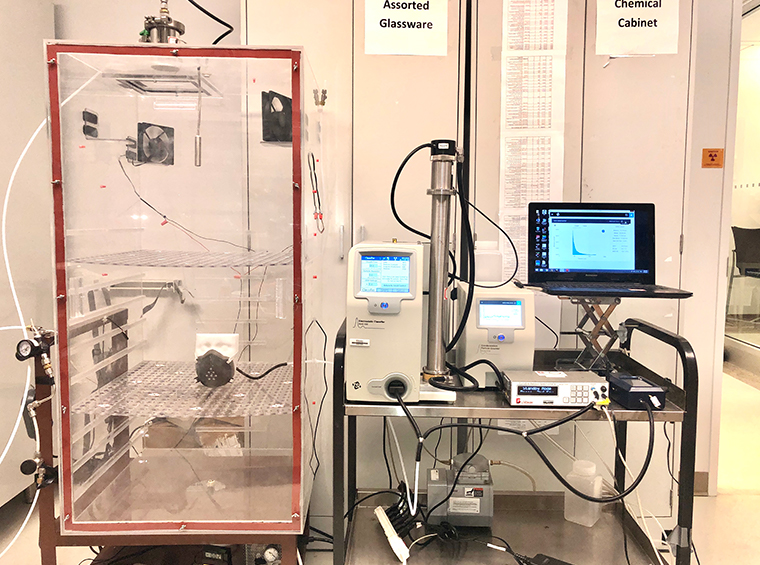

- 2nd generation emergency ventilator prototypes

- PAPR with a pending clinical trial and EUA

Related news story: Maker task force works to protect front line health care workers

The Process: The Maker Task Force executive team worked to understand how to best use these collective efforts to identify the medical supplies that were needed, build or source them to scale, and ensure they were delivered to the clinicians and patients who needed them quickly.

A variety of sub-groups within the Maker Task Force explored 13 different product lines in the following areas:

Face Shields, Masks & PAPRs

- Face Shields

- N95s

- Isolation Masks

- Cloth Masks

- Disinfection

- PAPRs

- Intubation Boxes

- Emergency Ventilators

- Ventilator Splitting and Multiplexing

- Ventilator Replacement Parts

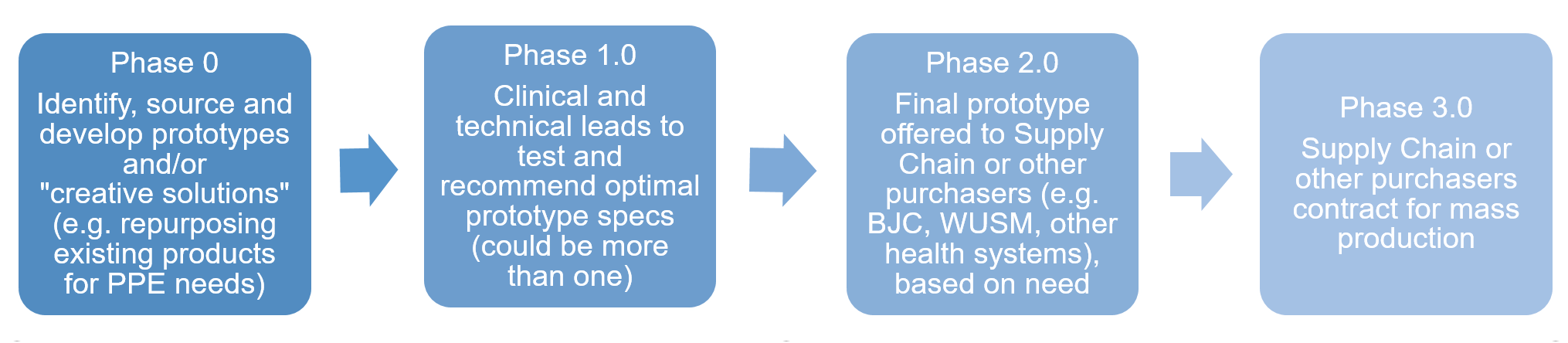

For each product line, the task force followed the following process:

Each of the 13 product lines have:

- A product line lead who serves as the primary point of contact between the product line work and the MTF executive team. As each product line develops prototypes or identifies alternative products, the product line lead is responsible for ensuring that the prototype or alternative product meets the minimum clinical and technical specs.

- Other clinical and technical leads who evaluate protoypes and provide technical expertise on the product line.

Some product lines have a supply chain task force lead, a representative from BJC Supply Chain (the entity that manages all PPE and medical supplies for inpatient operations at BJH and all other BJC hospitals). They keep the MTF executive team informed about the needs of the system. Based on BJC Supply Chain's needs, the task force will be sharing the current specs, quantities, and timelines that each product line needs to deliver on.

Maker Task Force in the news

The MTF executive team consists of Tom Maddox (WUSM cardiologist and executive director of the BJC/WUSM Innovation Lab), Ali Kosydor (director of operations for the Innovation Lab), Aaron Bobick (dean of McKelvey Engineering) at WashU, Eric Leuthardt (WUSM neurosurgeon and inventor), Philip Bayly (chair of the Department of Mechanical Engineering & Materials Science at WashU), and Kelli Delfosse (director of industry relations for McKelvey Engineering at WashU).